Photo Courtesy of Visual Tag Mx via Pexels

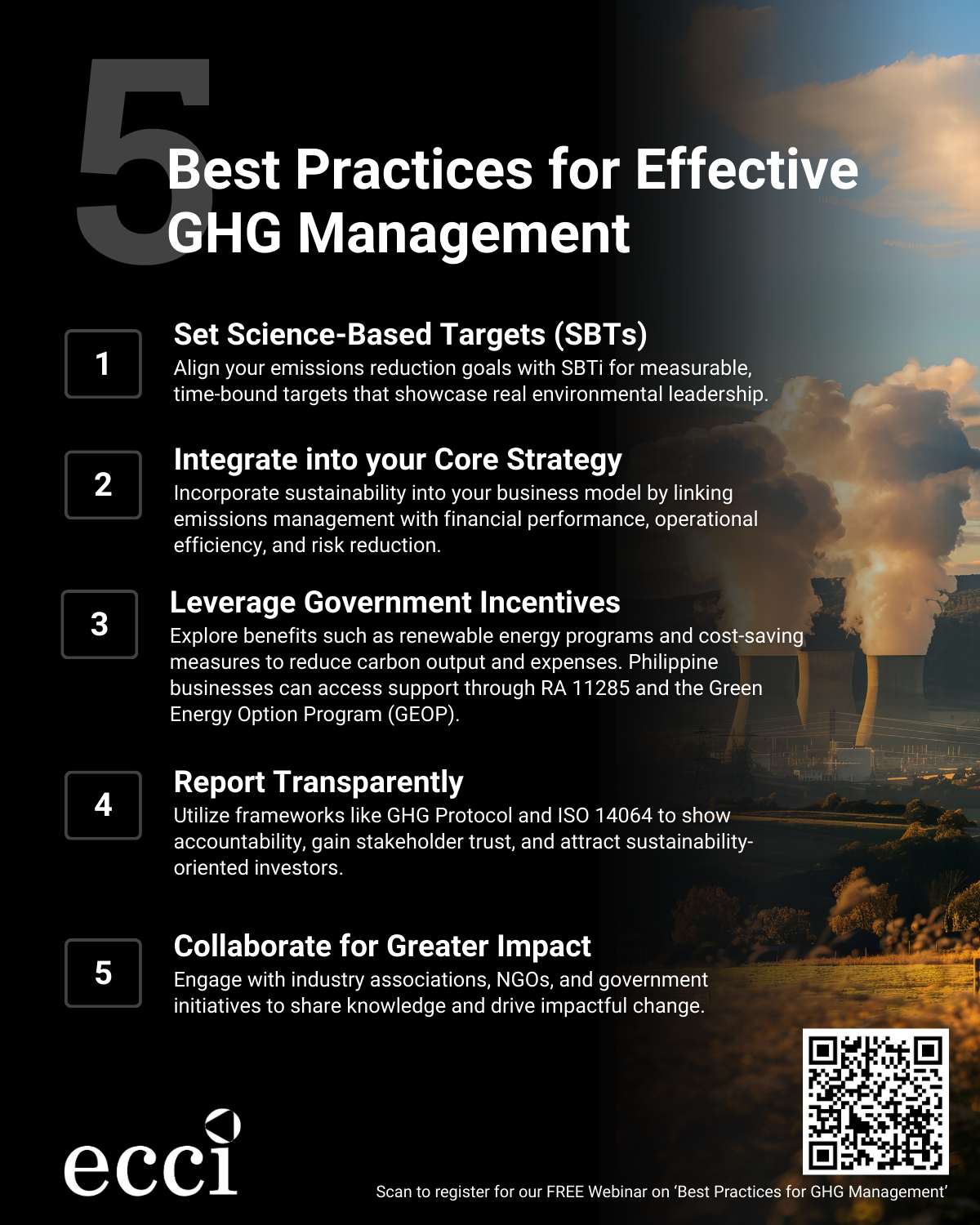

How do you know if your business processes are improving your bottom line? How do you decide whether or not to keep a cost-management strategy? The quick answer is through a quality process audit. Process audits are critical in the growth of businesses because they provide a way to assess operational efficiency and cost management. These are highly focused assessments involving “verification by evaluation of an operation or method against predetermined instructions or standards” (ASQ).

Process audits are conducted primarily to improve operational efficiency. Operational efficiency measures the efficiency of profit as a function of operating costs. A business should also always aim for greater operational efficiency which translates to greater profitability. You are able to generate more income for the same or lowest cost than an alternative. Operational audit techniques are key to attaining operational efficiency.

Why should your business conduct regular process audits?

These highly focused audits also help a business in various ways such as:

- knowing if strategies are delivering results,

- identifying any underlying problems, and taking appropriate action,

- showing to its market and customers that it is quality management system (QMS) compliant, and

- improving customer experience.

Quality process audits may not be mandatory for all types of business, but these are essential for those engaged in:

- Medical services

- Food safety

- Training

- Disability services

- Elderly care

- Financial services

- Manufacturing

- Wholesaling and retailing

Businesses that maintain physical stores benefit from store audits, which involve understanding business requirements and reviewing and analyzing data vis-a-vis performance. A store audit helps ensure you improve operations, boost bottom line and positively impact customer experience. This type of assessment suits the following businesses:

- Department stores

- Banking and financial firms

- Gas stations

- Telecommunication companies

- Cafes and restaurants

- Convenience stores

- Spas and salons

- Bayad Centers

How to conduct a quality process audit?

Photo Courtesy of Mohammad Danish via Pexels

A process audit evaluates the sequential steps and activities that create the action or transform inputs into outputs. It focuses on the work cycle and deliverables.

#1: Begin the audit by creating an actionable plan that will serve as a guidebook. You are free to develop a plan customized to your needs. A sample operational audit plan include the following common components:

Objective – This summarizes the reasons why the business or organization is conducting the audit

Criteria – This enumerates the tools used for this audit.

Scope – The audit scope or coverage states the areas of the business covered by the audit.

Performance indicators – These indicators are used to measure audit performance. Samples of performance indicators are the percentage of audit work delivered, audit report submitted and audit attendance.

People involved – The specific roles and responsibilities of each participant must be included.

Summary of activities – The summary indicates the key activities, dates and people in charge

Contingencies – This specifies the approach in allocating audit resources to accommodate unforeseen audit needs.

Reporting – This identifies the number of audit days relating to the production of reports.

Follow-up – This will ensure that recommendations are implemented on a timely basis.

#2: Collect and review documents including quality management policies, standard operating procedures and manuals.

#3: Develop a checklist for each audit participant. The items in the checklist shall vary per process and department. It, however, includes common sections such as environment requirements, measures to test, and quality system components.

#4: Conduct on-site reviews. The goal is to gather information needed to know whether an area of the business adheres to quality control standards and follows procedures. Observe, test, and conduct personal interviews. To avoid disrupting daily operations, perform the quality testing and interviews behind the scenes.

#5: Review the audit and identify quality issues and problematic areas. You should create a report detailing the findings in the audit.

#6: Set a strategy meeting with the managers and other decision makers to analyze and decide how to address issues and to incorporate solutions.

#7: Follow-up on the proposed solutions to make sure that the problems and issues are actually resolved. This is a critical step to lasting operational efficiency.

There are tools that can automate process audits. ECCI has helped businesses in Philippines to perform Store Audits through automated tools that are customized based on the business objectives. Process audits for stores can enhance consistency, value and customer satisfaction of each stores.

A quality process audit is a checkup on the health of your business or organization. A checkup is necessary on a regular basis, not only when problems emerge. An audit tells you whether your processes are producing your desired results.

For a truly effective assessment, you should consider applying Total Quality Management concepts to your process audit. These concepts include meeting and exceeding customers expectations, continuously improving quality and developing a culture of openness and trust across the organization. By aligning TQM and process audit, you can develop an audit system that revolves around customers needs and improving your business in the process.

Improve your business operational efficiency by running a process audit. Let ECCI consultants help you out. Set a meeting today!